PRODUCT LINES

Nail Base – Retrofit SIP Types

Innova’s energy efficient nail base and retro-fit SIP panels save contractors and building Owners time and money.

Our product flexibility allows designers to select the panel type required to achieve and / or exceed the energy code requirements for your project. Innova offers energy efficient panels in the thickness needed specifically for your project.

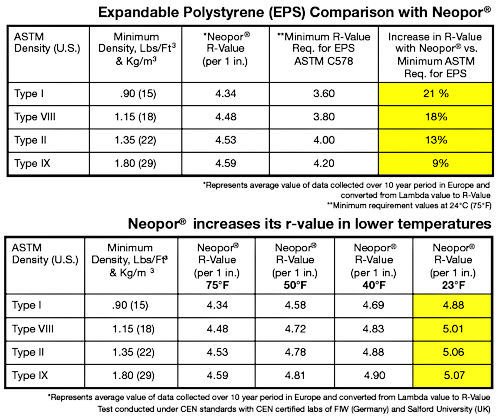

We offer our nail base panels with standard ASTM approved EPS or with Neopor® for added thermal resistance and energy efficiency. Neopor® is an excellent choice for projects with space limitations as it greatly increases the R-value over standard density EPS foam of the same thickness by using a graphite that is impregnated into the EPS.

The tiny graphite particles act as infrared absorbers and heat reflectors lowering the materials thermal conductivity.

The end result is a foam core with the same great advantages of standard EPS, however, with a thermal resistance (R-value) nearly 20% greater than standard white EPS. With Innova Eco Building System, we put technology in your hands as Architect’s, Contractors and end users can specify the SIP panel skin that best meets the needs of your project.

Panel thickness can be sized to meet the R values required by applicable energy codes. Innova offers our clients nail base panel skin choices of magnesium oxide board (MGO), James Hardie Cement Fiber Board, plywood and oriented strand board (OSB).

For more information about the many uses and construction details for nail base panel installations, please reference the Structural Insulated Panel Association installation guide. Nail Base Retrofit Panel installation guide for designers and builders

For more information about Innova’s Nail base

Retrofit SIP Panels, please click the panel type below:

* Neopor® can be added to any of the Innova SIP panels

to increase the R-Value even more!

more information about Neopor®

Neopor® is a graphite impregnated EPS … these tiny graphite particles act as infrared absorbers and heat reflectors lowering the materials thermal conductivity. The end result is a foam core with the same great advantages of standard EPS, however, with a thermal resistance (R-value) nearly 20% greater than standard white EPS.

NEOPOR contains no fluorocarbons.

Compared to polymer-based rigid foams which use fluorocarbons as expansion agents, NEOPOR uses a formula that achieves light-weight, cost-effective and durable foam with an expansion agent that has low Global Warming Potential (GWP) and Zero Ozone-Depletion Potential.

NEOPOR does not corrode, rot or support mold growth

NEOPOR Rigid Thermal Insulation does not contain cellulose or organic matter and does not rot or support mold growth.

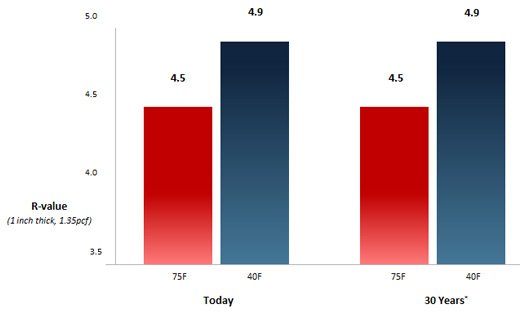

NEOPOR R-value is stable over time

NEOPOR does not corrode, rot or support mold growth

The R-value performance of NEOPOR Rigid Thermal Insulation is recognized in the third-party evaluation report #2784 from ICC Evaluation Service (ICC-ES). Building officials, architects, contractors, specifiers, designers and others utilize ICC-ES Evaluation Reports to provide a basis for using or approving NEOPOR in construction projects under the International Building Code. For more information, please visit www.icc-es.org